Commitment to domestic production! Hitachi's home appliance production line was Inspire The Next!

High -tech Hitachi production line to the workbench (Karakuri)

First, the manufacturing line of canister vacuum cleaners.This is what I am making.

表面のデザインが面白い紙パック式掃除機「かるパック」(CV-KP900G)The feature of this vacuum cleaner is "lightness" and "power to suck", which responds to the strong popularity of "vacuum cleaners".The suction work rate, which is an indicator of suction power, is 340W, about twice as much as a general cyclone vacuum cleaner.

It is a athletic vacuum cleaner that sucks the sand rubber in the back of the carpet with power.The secret is that the flow of the wind from the sucking mouth to the paper pack and the suction motor is straight, and there is no resistance.

吸い込みからモーターまでが一直線。理想的な空気の流れ左は水漏れしている市販の紙パック、右は日立純正紙パック。水漏れしないが空気は抜けるという微細な穴が開いている。※掃除機では絶対に水を吸い込まないでください。本実験はあくまでフィルター単体の性能比較ですCommercially available paper packs leak water, but Hitachi genuine paper packs are extremely small holes that pass only air without passing through water molecules.Even with fine particles garbage along with this paper pack and filter, 99.The feature is that 999%can be captured.

In addition, there is a worry that garbage accumulates in the rear part near the motor of a paper pack due to straight and powerful, and the eyes of the pack are clogged due to fine particles.If it is a general vacuum cleaner, it will be the time to replace the pack, but Hitachi has a bypass of air that sucks from the front of the paper pack, so there are some places where the suction power does not fall until the pack becomes garbage.It is a feature.

紙パックのモーターに近い部分の目が詰まっても、日立は紙パック前面から吸い込む空気のバイパス(赤い矢印)があるので、吸引力が長持ちIn addition, the design like the diamond cut of the main unit is reduced by reducing the ribs (beams on the lattice -shaped) on the back while maintaining the strength of the main unit, reducing the resin.

If you look closely at the cut, the triangle is a basic configuration, so it is a truss (combined triangle) structure like a iron bridge, bending, pulling, distributing compression and twist loading, and thinning the thickness.It seems to be kept.

よく見るとダイヤモンドのカットのような表面は三角で構成されている樹脂の量を減らし軽くしながら、強度を保つために梁のような骨組みを作る。この骨組みをリブと呼ぶBy the way, the site that makes such a vacuum cleaner is this.

これがキャニスター紙パック掃除機、かるパックを作る製造ラインのすべて! えっ! マジ!?You might think, "Well! Is it so small!?"

Only this is compact because it adopts a method called "cell production".Even now, there are many "line production", which is in charge of "one step per person" with long belt conveyors in a building that connects many gymnasiums.

In this case, hundreds of people, hundreds of people, such as "only" people who set up motors, and "only" people who tighten the screws.And those who are working are not very interesting (laughs).On the other hand, it is most efficient to mass -produce.When working with a robot, it is usually a line production.

家電ではないが、一般的なライン生産の現場

Conversely, in "cell production", assembly from beginning to end is alone.So it's interesting because the work has changed, and today we'll make it 30 seconds faster than everyone!The problem, however, is that you have to keep all of the ways to assemble one vacuum cleaner.Therefore, it takes about one month training period before going out on the production line and becoming a full -fledged line.

By the way, in the strict security factory, industry officials are interested, so let's stop on the workbench!

アルミパイプで組まれた作業台。目の前の棚は、ベルトコンベアになっていて、必要な部品が繰り出されてくるThe first thing that comes to mind is a "super" custom -made workbench that combines aluminum pipes (aluminum pipes from the texture), not the ready -made workbench.Usually, aluminum round pipes (PVC pipes for light products) are used, but they mainly use pipes with grooves that bite the clamp.Use a dedicated pipe with a rib with less resistance when gaining strength or sliding something.

The joints were very abundant, and they were all sitting (the screws do not pop out) so that they were hurt by the screws for fixing, and they did not hook the worker's clothes, eliminating unevenness.

切り欠きがあってクランプなどが挟めるパイプ作業台の構造体を支えたり、コロを使うまでもなくちょっとスライドさせるときに使われているリブ(ギザギザ)付きのパイプThe fine parts are in the parts box provided on the left and right, and have an angle of about 20 to 30 degrees so that it can be easily taken out.On the right is a drawer -type mini table that can temporarily place parts.If you want to make a product with many parts, it is likely that a parts box will be placed on this table.

It is also interesting to use the pipe cut end to make a pen or tool stand!

横の部品入れは、アルミのバットだったり、自分で作ったものだったり、各自異なる。筆者も良く使うコネクタ屋さんの空き箱だったり……パイプの切れ端に、汚れ落とし用なのか歯ブラシが刺さっていた。ここにペンを刺している人もThis landscape may feel uncomfortable for those who are used to the factory tour and industry officials.Yes, the back side is strangely refreshing.Normally, the karakuri that supplies parts (generally is a slope + roller, and the parts rack called "Karakuri" are called "Karakuri" from the place where parts are repeated), and the worker's hand is not visible very much.However, Hitachi factories have a conveyor supply of parts from the front, so there is no parts stock on the back.

The parts stock in front of the workbench has several rows of belt conveyors and large parts, such as the main body case, motor, cord reel (winding type), etc., so that the worker can reach out just by reaching out. It has become.

In a general factory, work efficiency is poor because it turns around, but in Hitachi, parts can be taken without looking at the workbench.It is interesting that if one part is taken out, the parts will approach from the back in conveyor.If you look closely, it seems that the infrared rays are always detecting whether the parts are in front of the worker.

目の前に本体上部のカバーとコードリールが緑のベルトコンベアに乗って迫り出される。部品棚兼、部品自動供給のカラクリになっているHitachi's cell production great technique does not end with this alone.Usually, the back of the worker who flows the finished product is the passage of an autonomous carrier that supplies parts.If there are no parts in front of the worker, the infrared sensor detects, and the automatic carrier runs to the cell to supply parts.

部品が不足すると、通常作業者の元まで行って数を調べ、足りないところには手動で補充する日立は部品搬送車の規定のレーンに部品を乗せるだけ。部品残数のチェックと補充はコンピュータ任せIt was a person who put parts on the autonomous carrier, but one person in charge of the day was one.In a general factory, the part supply car in charge of the parts walks around and replenishes the parts stock on the back of the worker's back, so it is significantly rationalized (in the case of line production, the worker's back is automatically moved.There are many places where transport vehicles carry parts, but in the case of cell production, it seems that there is a lot of human power because many parts are supplied to one person).

In addition, many types of parts can be posted on the autonomous carrier, so they run to the cell where the parts are gone, and the missing parts are sent in front of the worker with a belt conveyor.。

部品残数が少なくなったセルがあると、自動的に搬送車が走っていって、ベルトコンベアで作業者前の部品棚に補充するSurprisingly, the assembly work time.In the case of this vacuum cleaner, it is assembled on average in 4 minutes.Because it is an average, some people make it in the three -minute range, so it is surprising that it can be made in a shorter time than the line production.It can be said that it is a quick cell production line unique to Japanese who have small hands and have many dexterous people.

![lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool] lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/28016.jpeg)

![lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/30293.jpeg)

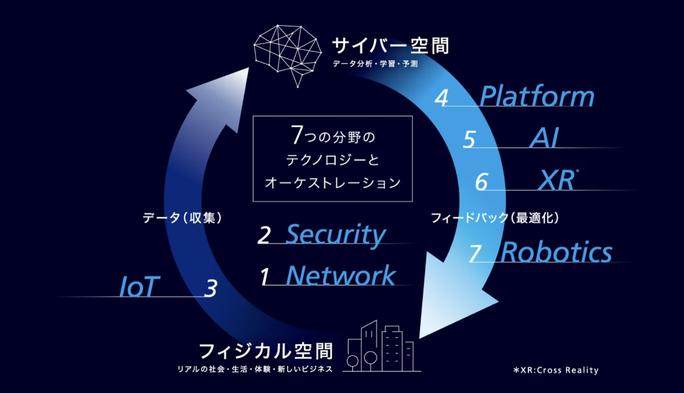

Will AI Concierge be realized in 2030? The future of KDDI's R & D (Part 1) | TIME & SPACE by KDDI

lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]

[2021] 11 latest recommendations for microwave ovens and ovens! Thorough explanation of how to choose

[A Certain Scientific Railgun] Popular character ranking TOP30!The first place is "Mikoto Misaka" [Survey results in 2021]