Most of JAL's in-flight meals are hand-made and visually inspected ``handmade rice'' I went on a social studies tour to Narita Airport's ``in-flight meal factory''

One of the pleasures of flying is the in-flight meal. I was excited to be able to infiltrate the in-flight meal factory specially this time. Why is the word “factory” so exciting? Machines that simply move inorganically can be watched forever.

However, the excitement was crushed in an instant. When I entered the factory, there was a person grilling meat. A person flips the meat by hand while checking the doneness of each piece.

On January 29th, 2016, I visited the in-flight meal factory of Japan Airlines (hereafter referred to as JAL), located several minutes away by car from Narita Airport. About 5,300 in-flight meals are prepared here every day. After changing into special clothes, we made preparations carefully to prevent foreign substances from entering the factory. The factory starts early in the morning, and preparations begin at 6:00 every morning.

Outside the factoryChange into special clothesThere are seven processes before entering the factory. You can't enter the factory without doing this1.Get dressed2.Brush3.Apply the roller to the clothes Remove small amounts of debris4.Wash your hands. There is a timer in front of the mirror, and it starts after holding your hand. Wash your hands with soap for 30 seconds, then rinse with water when the timer rings5. Kick your feet up on the mat 6. Drain the water off your shoes with a "draining mat" 7. Blow away invisible dust with an air shower Spinning until the wind stopsThe first thing I saw when I entered was this domestic sirloin of A3 size or above. It seems to be business class meat, and the marbled feeling is amazing. Here, you just add the grill marks, and the inside is cooked on the plane. After heating, cool to 10 degrees or less within 4 hours. The amazing thing is that everything is done by hand. I thought it would be automatically grilled as it was transported to the belt conveyor, but the person in charge was watching the grilling condition.

Looks really delicious...Each piece is carefully grilledWe use a machine to check the core temperature of the meat (the surface temperature for sirloin). All temperatures are meticulously recordedThe finished meatNext, we were guided to the place where liquids such as sauces and broth are cooled. These are cooled using water.

A pot of dashi is submerged in waterThe liquid is cooled hereA huge quick refrigerator that cools meat to 10 degrees or less small>Cold on a tray in the refrigeratorThorough temperature controlThe next place we visited was the "cold kitchen". Ingredients that had been cooled to below 10 degrees Celsius in the huge rapid refrigerator mentioned earlier were brought here, and work was being done to cut the crusts and tomatoes for the sandwiches. To prevent contamination, the tray and gloves are colored blue, which is not found in food. All knives are numbered and checked before and after use to prevent the wrong knives from being carried on board. The checkered ballpoint pen is also special because it has no cap and cannot be disassembled. No springs are used.

This is the Cold KitchenAt the time of our visit, they were making sandwiches for business class and first class. Even so, it looks delicious...Cut off the crust from the bread. Blue trays and glovesCut tomatoesThis is the team that makes "special meals" for vegetarians and people with allergies. Work on separate tables to prevent even the slightest contamination.The number "N27" engraved on the knifeManage the usage status by writing it down on paper.< small>Special pensBread and desserts are made at the "Pastry Kitchen". The serving, whipping and squeezing the whipped cream are all done by hand. Everything is really hand made... They bake 200 loaves of bread a day.

Everything is done by handServingWhiskingPastry KitchenBetter than freshly baked The quick freezer (the white one on the left) says that it tastes better. This is where sponges are frozenBread making tools. All the tools you've seen beforeHere, too, there is a device to prevent contamination. A dedicated "opening place" is set up for opening plastic bags such as bread bags, and it can only be opened here. There are detailed instructions on how to cut the bag. There is only one place to remove the plastic "pull top" attached to the bag of bread, located a short distance from the kitchen.

A place where plastic bags such as bread bags are openedA pull-top opening place located slightly away from the kitchenNext, visit the "Dishing Kitchen" . In the kitchen dedicated to presentation, the final presentation is done based on the sample. Particular care is taken here to keep dust out, and long white sticks called 'sock tucks' are attached to the ceiling so that the air from the air conditioner can flow throughout. Doors that are closed to traffic are also conspicuous to prevent insects from entering.

"Sock-tucks" on the ceilingMost of the doors are "closed"A view of the arrangement. Detailed instructions are written on the serving sample.This is where I encountered the machine for the first time. It's a metal detector. Put the packed pack through a metal detector for a final check. This metal detector detects iron up to 2mm and stainless steel up to 3.5mm. Before starting work, he always checks that the metal detectors are working properly.

Metal detector. Packs that have been packed pass through this long lane2mm iron and 3.5mm stainless steel plates for checking with metal detectorsThe packs that are completed in this way are called "meal sets". It is set on the tray in a dedicated space called . All this work is actually done by hand. Water, salad, fruit, and other items to be placed on the tray are prepared for the same number of minutes, and if even one is left over, all trays are checked. Once the trays are placed in a cart that is loaded onto a truck, it is finally ready for shipment. "Here we have a lot of trays, but for the customer it's just one tray. That's why we set trays one by one so that there are no mistakes."

Japanese plate in business classPlate in economy classEverything is done by handTray is loaded into the cartLock the cart tightly with a key so that someone cannot open it on the way. In-flight meals are shipped about three hours before the plane flies. The trucks are transported under thorough temperature control of 20 degrees or less. Not only from a sanitary point of view, but also from the point of view of security, it is extremely important not to let sick people out in the sky.

Strictly lockedLastly, I was guided to the food storage room and the bacteria inspection room (quality control room). In storage, the temperature is controlled for each type of food, such as meat, seafood, and vegetables. The discovery here is that huge meat and a large amount of vegetables are not placed like commercial ingredients. Every day, only the amount of ingredients used for the day is delivered, and detailed records are kept of which meat was used on which flight. Visually check for dirt or insects.

Food storage with household sized itemsSeafood refrigeratorA huge refrigerator with small trays of fish We areMeat is also a block. Start with the smallest numberVegetables are so compactThey come to pick up what you needThis is in the freezer. For safety reasons, two or more people enter the giant freezer.In the bacteriological laboratory, food, cooking utensils, and employees' hands are inspected every day. As for the inspection frequency, all types of cooking utensils are inspected within a month, and hands are inspected once every two months. Before the menu change and in the summer, the frequency of inspections has increased and it is said that it is busy. Based on the results here, cooking methods and cleaning methods have been improved, and we are also collaborating with the site, such as direct instruction.

Testing using culture mediaJAL's in-flight meals are made by hand every day. I was surprised at this fact, and the person in charge explained the reason as follows: "Actually, I've measured the time between manual and machine work. As a result, the manual work was clearly faster. On board JAL. When it comes to food, there is a lot of small-lot, high-variety, and there is a lot of detailed work. Changing the menu four times a year to match the season is something that cannot be ruled out for the enjoyment of our customers.

There are currently about 80 people working here. The person grilling meat, the person cutting the crust of the bread, the person serving the food, the person lining up the tray, the person locking the cart containing the in-flight meal, the person conducting the inspection, all of them are "security personnel". was working.

Business Class Japanese FoodBusiness Class Western FoodEconomy Class Western FoodChild MealsCute child meals like this are 2015 Offered from year. A project was formed by four women with childrenThere are people who often say, "In-flight meals don't taste good." The author who says so is one of them. However, after the factory tour, I felt like I had a glimpse of just how difficult and risky it is to serve food in the sky. In-flight meals are not dishes that can be served immediately after cooking. If by any chance you get sick there, the plane may have to turn back. In-flight meal provided in such a situation.

By the way, the freshly prepared in-flight meal in business class was so delicious that I had the illusion that I was in a high-end restaurant.

(Tomomi Ota)

Related Articles

Copyright © ITmedia, Inc. All Rights Reserved.

![lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool] lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/28016.jpeg)

![lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/30293.jpeg)

lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]

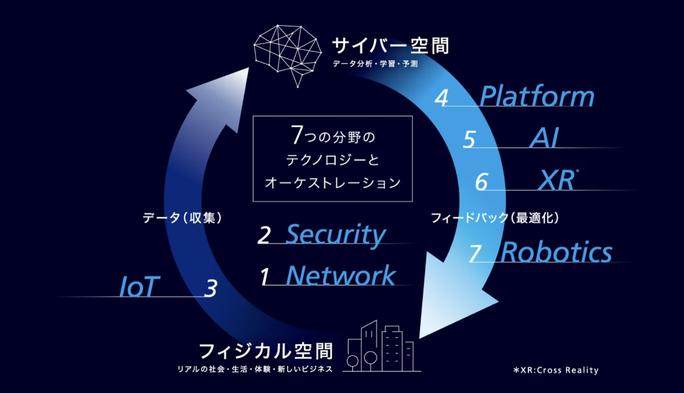

Will AI Concierge be realized in 2030? The future of KDDI's R & D (Part 1) | TIME & SPACE by KDDI

[2021] 11 latest recommendations for microwave ovens and ovens! Thorough explanation of how to choose

Recommended for studio rooms living alone, 5 "storage furniture" 5 selections and Yamazen are available in affordable furniture!