LG Changwon smart factory where robots carry packages and manage with AI (THE Korea Economic Daily Global Edition) - Yahoo! News

Delivery

2 comments 2A robot that assembles a refrigerator at the LG Smart Park integrated production building in Changwon, Gyeongsangnam-do (Provided by LG Electronics)

The LG Smart Park in Changwon, South Gyeongsang Province, the production base of LG Electronics' home appliances, has been transformed into an intelligent autonomous factory. It is a state-of-the-art facility where the production system is managed by big data and robots transport materials and finished products. The industry is expected to spur the transformation of major companies into smart factories. This is to prepare for the prolongation of the new coronavirus and the spread of the trend of high-mix low-volume production. O Expectation for 30% reduction On the 16th, LG Electronics held a ceremony for the completion of the first integrated production building at Changwon LG Smart Park. LG Smart Park is the new name of the Changwon office, selected through employee recruitment. LG Electronics has invested a total of 800 billion won (approximately 75.4 billion yen) to transform its former Changwon 1st factory, which produces kitchen appliances, into an eco-smart factory. Three lines of premium-grade 'LG Signature' refrigerators, general refrigerators, and water purifiers started operation on the same day. It is characterized by integrating the production lines for each product, which had been scattered in individual buildings, into a single production building. The remaining three lines are planned to be completed by 2024.

LG Smart Park

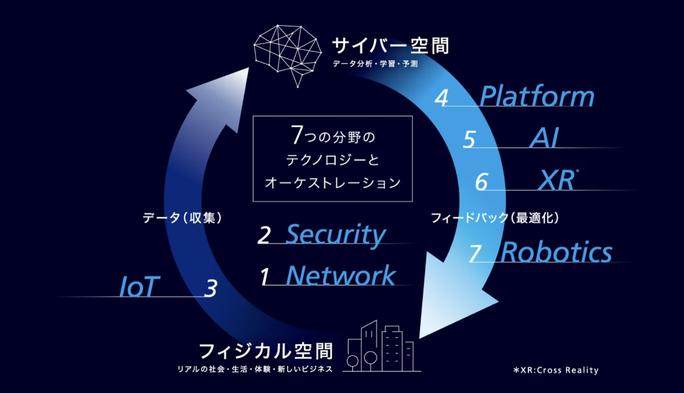

In the construction of the integrated production building, cutting-edge technologies such as big data, artificial intelligence (AI), and robots were mobilized. Technologies such as intelligent unmanned warehouses and high-altitude conveyors were introduced for the first time. The use of robots has also expanded. LG Uplus's ``5G dedicated network-based logistics robot'' has been introduced so that the robot can transport materials within the factory. Once the integrated production building is finally completed, the annual production capacity of the existing Changwon No. 1 plant, which was at the maximum level of 2 million units, will increase to more than 3 million units. LG Electronics commented that the conversion to a smart factory helped revitalize the local economy. Currently, 11 LG Electronics subcontractors in Changwon have 4,100 employees, up 10% from the previous year. 160,000 workers from construction companies in 22 regions also participated in the smart factory construction project. An energy saving effect is also expected. State-of-the-art facilities such as ``Beacon,'' an energy management solution for buildings, are expected to improve energy efficiency by about 30%. Ryu Jae-chul, LG Electronics H&A Business Headquarters (vice president), said, "We want to make Changwon, which has built the industry's highest standard production infrastructure, a base for capturing the global premium home appliance market." Experts expect more companies like LG Electronics to remodel into smart factories. This is because it is the only way to increase production without securing land for a new factory. Currently, it takes two to three years to build a large-scale production facility like LG Smart Park in Korea just for permits, land compensation, and securing electricity and water. It takes one to two years to build a factory, bring in equipment, and conduct tests.

Page 1/2

![lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool] lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/28016.jpeg)

![lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/30293.jpeg)

Will AI Concierge be realized in 2030? The future of KDDI's R & D (Part 1) | TIME & SPACE by KDDI

lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]

[2021] 11 latest recommendations for microwave ovens and ovens! Thorough explanation of how to choose

[A Certain Scientific Railgun] Popular character ranking TOP30!The first place is "Mikoto Misaka" [Survey results in 2021]