Aladdin's classic retro stove with blue flames. I've seen skilled craftsmanship at the factory! --Home Appliance Watch

news

August 3, 2021 07:00

Sengoku is a manufacturer of "Aladdin" products that have become famous for toasters. In fact, in addition to toasters, we also manufacture electric heaters, oil-electric hybrid heaters, and oil stoves, gas stoves, and stoves. Moreover, it also manufactures and exports products for the ASEAN region, Europe, and the Middle East. Surprisingly, we also do OEM for major Japanese manufacturers. OEM destinations are not limited to major home appliance manufacturers, but also cassette gas manufacturers and solar hot water supply.

What surprises me about Aladdin is that the stove with an ultra-retro design is still the main product. It is a convection stove called "Blue Frame Heater". The convection type is a stove that warms 360 degrees around the main body, which is often seen at stations on local lines in snowy countries, and is ideal for heating large spaces.

Unlike a general kerosene heater with a reflector, it is a hit product that has been loved by Aladdin for many years because it is popular for warming the entire room. This stove isn't manufactured year-round, and not every day during the manufacturing season. I had been requesting to see the site from before, but there was a day when it was just manufactured, so I was asked to show me a valuable manufacturing site.

Even though it's an oil stove, it's a blue flame! This is Aladdin's craftsmanship.

There is a reason why Aladdin's convection stove "Blue Frame Heater" is popular. The flames of common reflective and convective kerosene heaters are orange or yellow. However, as the name implies, the blue frame is a blue flame like gas. The blue flame is a color that can be seen only when kerosene is completely burned, and it is hot and has almost no soot.

In order to make a blue flame, it is important to balance kerosene, core and air, and in an oil fan heater etc., once the oil is heated with an electric heater etc. to make it into a gas (vaporization), air is forcibly sent in. It is burning with a blue flame.

However, Aladdin's Blue Frame has no mechanical mechanism. Although it is necessary to adjust the wick manually, once ignited with a match, it naturally sucks in air from the bottom of the stove and uses heat convection to send air to the inner and outer flame cylinders of the combustion part. It has become. In other words, everything is left to nature, and the color of the flame is determined by the adhesion of the parts that create the air flow and the salt plum that has a slight gap.

This is the ultimate in functional beauty! 100 years history of Aladdin Blue Frame

If the golden burning parts made of brass are distorted even a little, the blue flame will not come out, and it will be a lot-out product as a blue frame. Therefore, in the era of mass production, each Aladdin blue frame is handmade by a craftsman.

In this way, there are almost no mechanical parts, and each part can be removed, disassembled, cleaned, and assembled, so many enthusiasts have been using the same stove for decades. Aladdin's stove is also a collector's item.

For nearly 100 years since the prototype appeared in the UK in 1919, the design has been changed little by little and the safety has been improved in detail to comply with the law, but the basic structure is exactly the same. Not only is the design retro and nostalgic, but the functional beauty that uses the minimum necessary natural power is the characteristic of Aladdin's "Blue Frame Heater".

Aladdin's stove factory is just a secret base for craftsmen

The assembly of the Aladdin stove is mainly divided into the lower part of the tank and the combustion part, and the upper part of the cylinder. Moreover, each assembler is two older sisters who have been making stoves for many years.

The width of the line is about 8 tracks running 50m. In the corner of the factory, the parts of the stove pressed at the company's factory are collected, and the final assembly is done here.

There are no high-tech lines, and the work procedures and production target values are not digitized at all. After all, the craftsmen who have been making stoves for decades, so the assembly procedure is at a level that the body can remember. The only thing that seemed to be a factory today was a whiteboard with the number of production per hour, the target number, and the number of production per day.

To assemble the upper part, insert mica (transparent film-like ore. By the way, I don't know the company that uses it for the window of the stove now) in the tubular part, and attach a safety frame and so on. The characteristic is that it is a blue flame that burns completely, so soot hardly comes out, but it also has a catalyst just in case.

On the other hand, the lower part is mainly an oil tank. This tank, in fact, is donut-shaped and naturally aspirates fresh air from under the stove with the heat of the flame in the combustion section. What's more, it's not just sucking in, but because it has a rectifying plate, the air doesn't swirl.

A core made of cotton is attached to the upper part of the tank, and a combustion part called an outer flame cylinder and an inner flame cylinder is attached so as to surround it. The size, number, and position of these holes have hardly changed since the first generation, and parts of the same standard are still used. At the end, an automatic fire extinguishing device and a fuel gauge in case of a fall are attached, and it is completed by combining with the upper part.

The last is a full inspection. All finished products are ignited to see if the flame is blue. If even a part of it is incompletely burned, recheck it by scraping the inner flame cylinder and outer flame cylinder of the combustion part with a file or adjusting the shape.

I went to the factory tour in July, and two months had passed since the start of production in May, so the parts were stable and a stable blue flame was seen. However, it is said that it will not be decided in one shot in May when it starts to be manufactured.

At the end, when it is completely cold, it is packed with vinyl. The number of stoves made in this way is 100 per day. However, it is not manufactured 365 days a year, but only a few days a week from early summer to autumn. This is because the craftsmen who work here are not only doing blue frame stoves, but also OEM production by major home appliance makers.

Beauty and structure that have not changed for 100 years are valuable assets

Aladdin's blue frame heater is extremely popular and has a strong attachment because it is handmade one by one and repair parts can be obtained in units of the smallest parts. Carefully, there are only a few stoves that can be repaired and repaired for decades. In fact, if you search for "Aladdin stove repair" on the Internet, you can find many YouTube videos as well as the homepage, such as "I repaired this by myself, I maintained this" from buying and selling parts.

Sengoku / Aladdin's manufacturing is made with sincerity in both home appliances and stoves, and we are making products that are truly loved by users. Looking at the factory, I felt that kind of thing again.

Aladdin's stove is not just an industrial product, it has a blue soul flame.

![lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool] lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/28016.jpeg)

![lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/30293.jpeg)

lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]

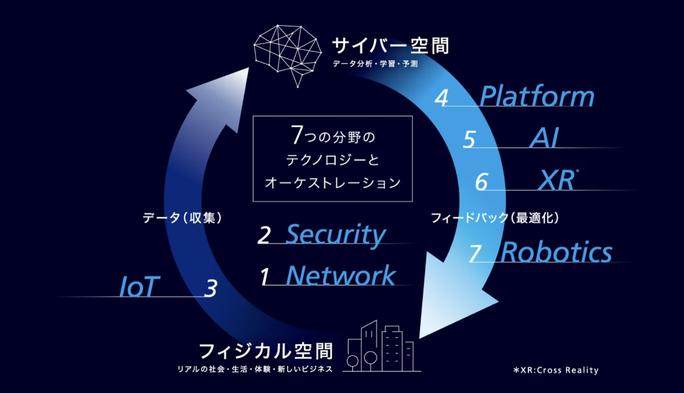

Will AI Concierge be realized in 2030? The future of KDDI's R & D (Part 1) | TIME & SPACE by KDDI

[2021] 11 latest recommendations for microwave ovens and ovens! Thorough explanation of how to choose

Recommended for studio rooms living alone, 5 "storage furniture" 5 selections and Yamazen are available in affordable furniture!