Can vertical farming feed the world? : Agricultural Venture Infarm Challenge (Part 2) | WIRED.jp LargeChevron Menu wired logo Chevron Close wired logo Newsletter icon-picture wired logo Newsletter

* Continued from the first part

The concept of vertical farming is simple. Instead of arranging the crops in the field, they are cultivated by stacking them vertically. Using artificial light instead of the sun, producers usually use nutritious water where there is soil. For "Aeroponics", use a mist that is evenly sprayed.

Vertical farming uses less land than traditional farming. It uses little water, does not flush contaminated pesticides into the ecosystem, and can be built where people actually live. But overall, it's not functioning as a business. Profit can only be gained from cannabis in the black market and the Japanese food ecosystem, which is well-stocked and has a lot of imports. Building a medium-sized vertical farm costs hundreds of thousands of pounds and uses exorbitant energy.

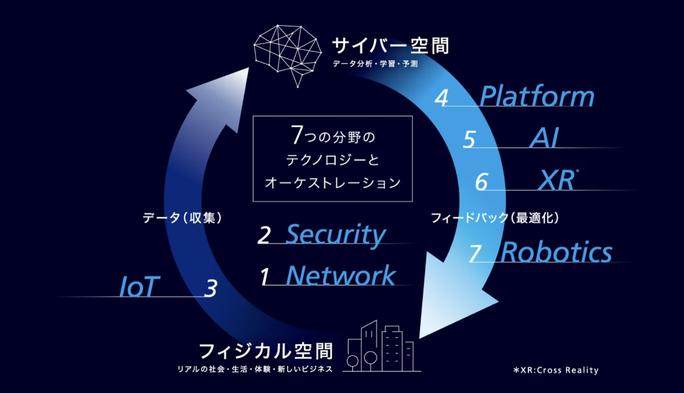

Technological advances are changing this situation. Incorporating automation, machine learning, and cloud-connected software into vertical farming has enabled businesses to reduce manual labor, increase capacity, and cope with fast-paced changes during cultivation.

Automation revolution

Infarm staff, who work in a separate office from Berlin's new farm (in the Tempelhof district, about 23km southeast of Spandau), have a huge CCTV room-like "Farm Control Cloud Platform." Through, we are tracking "plant recipes" set in any of the 1,220 in-store units, such as CO2 level, pH, growth cycle, etc. Machine learning optimizes the recipe and keeps each plant as uniform as possible.

Gertenfeld Island employees, such as mechanics, electricians, software developers, crop scholars, and biologists, are by the side of the crop, but barely. Employees monitor via iPad and feed crops to four huge farms inside the building. Each cultivation room is about the height and width of two London buses and is equipped with a modest turbine hall-like sounding ventilation system.

From that point on, the robot works hard. Inside the farm, a robot called a "plant retrieval system" -a machine like a big UFO catcher-moves up and down vertical beams, lifting trays of plants in different stages of growth and climbing to the top. Move closer to or further away from the LED light. According to the company, this will reduce work time by 88%.

The device can be seen directly from a narrow window in only one place, but the rest are all sealed to prevent pests. "In the case of automation, once you invest, the price of your crops goes down over time," said Orie Sofa, head of the In-Farm Hardware Laboratory. "Unfortunately, in the human workforce, prices go up over time."

The type of crop depends on the amount of production, but each "farm" usually grows just under 300 crops at a time. Each farm yields as much as 10,000 square meters of land and uses only 5 liters of water per kg of food (traditional vegetable cultivation uses about 322 liters of water per kg).

This revolution goes beyond in-farming. AeroFarms, a startup based in Newark, NJ, sprays aeroponics mist on its roots, which are covered with a cloth and separated from the leaves. The most recent funding round was led by Ingka Group, the parent company of IKEA, a leading Swedish furniture maker.

Bowery Farming in New York, like in-farming, focuses on automation and uses a unique dashboard called "BoweryOS" to take real-time photos of crops for analysis. .. The company's £ 123m is funded by investors, including Singapore's sovereign wealth fund Temasek. Bowery CEO and founder Irving Fein said of the company's available markets: "It's a crop we think is appropriate, and it's about $ 100 billion a year in the United States alone." ing.

Leading the vertical farming Venture Capital'(VC) race is San Francisco-based Plenty, which has raised £ 500 million since its inception in 2013. Includes a 20-year Series D round led by Masayoshi Son's $ 100 billion SoftBank Vision Fund. Plenty grows vegetables with water dripping from a 6m high stanchion, and an algorithm adjusts the plant growth recipe according to the data sent from the infrared sensor.

Two USPs in the farm

Nate Story, co-founder and chief science officer of Prenty's test farm in Wyoming, likens these deep-tech solutions to the tools that underpinned the recent agricultural revolution. "Tractors have freed farmers from shackles. Half of the land was once used to raise livestock, but with the advent of tractors, they were freed from the life of caring for animals to cultivate the land. Is. "

Automation is similar for farmers, the story says. "The hardest job-the unpleasant job or the job that (the producer) doesn't want to do-is gone, and you can focus on what really matters."

Infarm has a different strategy than its rivals in two respects. The first is that we are focusing on module design. Each compatible and extensible component looks like a huge and noisy Lego set. Thanks to the modularity, in-farm units can be installed anywhere in the world, regardless of size, in weeks.

And this is what enables the company's second USP (unique strength) business model. In-farm sells its products through remote units without having a store.

Clients tell the in-farm what crops they want and "make a schedule," says co-founder Osnat Mikaeri. "Once a client buys a plant, everything on the farm is controlled by Tempelhof. Everything grown is the client's."

For example, a chef may need pesto made from Greek and Italian basil that has been aged for three days. In-farm can meet that demand (Berlin's most famous chef, Tim Raue, is an in-farm customer). "Everyone stops and asks about this farm," said the manager of a store in Berlin. "It's great to have innovation here."

"There are two major advantages to Infarm," said Nikola Carslake, founder of Nevada-based Agtech investment firm Contain Inc. "One is to establish a means of on-site production, which is by no means easy, and the other is to have good relationships with large customers like Mark & Spencer."

"Where is the arms race in the industry?" She continues. "It will be concentrated in two areas. How can I get as much capital as possible, how can I sign a contract with the right partner? Very useful if Mark & Spencer is behind me. is"

It also encourages investors to open checkbooks. Hiroyuki Tamura, a partner of London VC Atomico, met the three founders of Infarm for the first time in 2018. A year later, Tamura led a £ 75m Series B round. "The three founders were able to develop their business in earnest," says Tamura. "It worked, and I didn't need an industrial warehouse for it. I fell into a rabbit hole in a blink of an eye. It was an amazing experience. Wow, these guys took the time and speed. With that in mind, I'm trying to sell modularization. "

Interlocking hardware and AI programs

Infarm returns part of its revenue to research. Twelve lab coated analysts test herbs to Ariana Grande's soundtrack in a mezzanine lab above a farm on Gartenfeld Island in Spandau, west of Berlin. , Crop sugar content, acidity, vitamins, toxicity, antioxidants, etc. are measured. Through a process called "phenotyping" that examines the characteristics of living things according to the environment, we are trying to create more flavorful plants and completely new tastes.

"This isn't just a hardware issue," says Contain, Inc. Carslake. "It's important how the hardware interacts with the rest of the farm system, and it's getting pretty sophisticated in this regard, because the AI these companies started three to four years ago. Because the program is now beginning to bear fruit. "

The company's products are of high quality. Fresh lettuce, punchy wasabi rocket, and basil that is incomparably fragrant to cheap ones. "The ultimate goal of almost all of our work is to develop a modular and standardized system, like some kind of playbook, that can be copied and pasted everywhere," he said. , Infarm Plant Science Director, Pavros Caraizo Glue.

In-Farm Crop Science Director, Pavros Karaizo Glue. In a laboratory in Berlin. PHOTOGRAPH BY ÉRIVER HIJANO

Opposite the lab, tomatoes and shiitake mushrooms are cultivated in a room about the size of a wine cellar. These are proof that the company is exploring diversity in addition to herbs and leafy vegetables, which are the main crops of today's vertical farming business due to their low energy and water consumption.

We are on the verge of destroying the planet through agriculture. Agriculture already occupies 40% of the habitable land on the planet, and food production causes a quarter of all greenhouse gases. Scotland-sized rainforests, which are responsible for up to a quarter of the land's photosynthesis, disappear every year. Further deforestation to support a rapidly growing population does not help.

"We need to go back to the beginning and rethink the path we can pursue environmentally," said Nikola Cannon, a professor at the Royal Agricultural University of Cirencester. Nitrogen fertilizers are particularly harmful to the environment, Canon continues. "We ended up adopting a system that well exceeded the limits of this planet."

The current food system is extremely inefficient, with waste accounting for 25% of total calories. Nevertheless, nearly a billion people around the world are suffering from hunger. Critics argue that these are not problems that can be solved by vertical farming. Local production for local consumption will satisfy consumers.

Energy is also a tricky problem. 90% of the current in-farm electricity is renewable and we are aiming for zero emissions in the next few years. However, this does not take into account the environmental costs of constructing steel and cement facilities.

The key "Haitz's law"

"Vertical farming is only a small force in terms of contributing to the big trends in the world," says Minneapolis-based environmental scientist Jonathan Foley. "Like most technologies that have acquired a lot of VCs and were born out of Silicon Valley thinking, vertical farming is over-proclaimed at the expense of real-world solutions. These technologies, funding, and (and other things needed). It costs an opportunity to put (usable) recycled energy into arugula cultivation for wealthy people, which is $ 10 per oz (about 28ℊ). "

More than half of the world's food energy is supplied by three "mega-crops". Wheat, corn and rice. These require winds, seasons and micronutrients that cannot be reproduced by current vertical farming. It is these crops, not lettuce, that can prevent famine in Somalia, Bangladesh and Bolivia. "Vertical farming grows the edges of the plate, not the center of the plate," Foley says.

But Columbia University professor Dickson Despoemier says it's too early to criticize the young industry for not being able to address issues such as crop diversity. "What we're actually seeing now is that vertical farmers are taking a step, turning their books into the black, and rushing to make money to reward investors before they start diversifying. is"

"In a world where land and resources are considered endless, indoor farming wouldn't make sense," says Plenty co-founder Story. "It sounds like it's not as crazy as replacing the sun with electricity, but it's rational today, and as time goes on, it becomes more and more reasonable."

Most of the expectations of vertical farming rest on light emitting diodes. This little beaded light is an industry wagon. In short, it occupies the largest position in the farm's finances and is at the core of the most exciting progress. Modern LEDs are completely different from the ones used on television when you were a kid. The progress has been remarkable, and in fact, a unique law to be observed, "Haitz's Law" -every 10 years, the cost is reduced by a factor of 10, and the amount of light produced jumps 20 times.

Experts say the curve will eventually flatten. But that's only after LEDs have improved their performance and vertical farming can benefit from food near the middle of the plate. In-farm's current smart LED devices are more than 50% more efficient than those used on the first farm. Haitz's Law helps companies experiment with growing potatoes, which require much more energy and water than leafy vegetables. It's important for the industry to profit from the crops with the highest calories per acre.

Today's state-of-the-art LED technology is smart sensors that adjust the brightness and spectrum of light to reproduce or enhance outdoor cultivation. Most of the planet's first flora grew only in the ocean, but the ocean looks blue because it absorbs very little blue light. Therefore, photosynthesis is most active between the blue and red light spectra. Vertical farming can further reduce the energy burden by lighting the LEDs only in these colors or dimming them to the natural cycle of the plant (for example, to speed up the road car). It's like making it as light as possible).

Recent discoveries have brought even more surprises. For example, strawberries are particularly responsive to green light. There are also specific spectra that increase vitamin C in concentrated fruits such as kiwi, and spectra that can extend the best-by date by nearly a week. In the future, says LED company Heliospectra grower Faye Jar. "We can get feedback on how to illuminate the lighting and the plants themselves to further improve the stability of crop quality."

"Judging from what we have, we can understand what [critics] are saying," says Infarm co-founder Guy Garonska. "How do you grow rice and wheat to save the world? That's true, but critics don't see a decade ahead. There are various trends that should eventually support this reform. There is no such thing. "

Approaching true self-sufficiency

Other technological advances are also supporting agriculture in many ways. Drones and sensors contribute to the mapping and rationalization of cultivation. Drip irrigation dramatically reduces the burden of declining water resources. Recycling production (where waste generated in one process becomes fuel for another process) is becoming more common, especially in the livestock industry. Cell culture and insect-based meat (or vegetarianism) reduce reliance on livestock, which consume 45% of the world's crops.

A wide range of vertical farming companions, including in-farm, may not be saving the world right now. But he wants to build more high-rise farms and install them in public facilities such as schools to teach people the value of fresh and healthy vegetables. Once 70% of the population lives in the city, the city "can become such a growing community," says Infarm co-founder Elles Garonska.

Ultimately, Infarm is aiming to build an automated tens of thousands of farm networks, with data coming from each farm to Berlin's huge AI system one after another. This "brain," as Garonska calls it, puts this information into algorithms to produce quality food at low cost and gradually reduce the water, energy, and nutrients needed for each new harvest. I will continue to do it. Infarm thus approaches her dream that Garonska has left in the Canary Islands-her true self-sufficiency.

Garonska has come a long way from the leaky handmade gadget that Garonska made with her other two in her living room. "Now the world is clearly in the wrong direction for everyone," says Galonska. "We believe in the power of collaboration 100%. With ideas that are not bound by preconceived ideas, we will bring more, higher quality food, more sustainability, and new systems that will help heal this planet. I believe we can build it-because that's the main issue we need to tackle right now. "

![lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool] lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/28016.jpeg)

![lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/30293.jpeg)

Masaki Aiba's "VS Damashii" member theme song project started!Shori Sato & Yuta Kishi laugh at orders in English

We take the place of ... Children who directly appealed to His Majesty the Emperor for the release of his father in the Nara period (December 11, 2021) --Excite News

The 26-year-old who doesn't know love met ... "Literature Virgin-The Story of Late Blooming Love-" (November 22, 2021) --Excite News

How can I create music with Deep Learning? -Builders.flash ☆ -Builders.