Supports restaurant sustainability. The future of circulating tableware drawn by Western tableware maker "Nikko" | World's Social Good Idea Magazine | IDEAS FOR GOOD

What comes to your mind when you hear "food sustainability"? Many people may think of social issues related to food itself, such as food loss and the problem of climate change related to industrial livestock.

However, when considering food sustainability and circulation, we must also look at the products, services, and mechanisms that support food. One of the best is tableware.

Nowadays, it is difficult to procure high-quality soil and stone resources, which are the raw materials for tableware, due to over-mining and residential land development due to rising demand. On the other hand, especially in the hotel / restaurant industry, which handles tableware for business use, it is not uncommon for tableware to be discarded even if it is chipped or the pattern is peeled off from the viewpoint of maintaining service. The current situation is that the value chain for tableware is unavoidably a linear system of mining, manufacturing, utilization, and disposal.

As with food itself, it is important to draw a path for shifting resources from a linear model to a more circular model when considering the sustainability of tableware.

Nikko Ceramics Co., Ltd., a Western tableware maker founded in 1908 based in Ishikawa Prefecture, has begun to seriously tackle the transition to the circular economy of tableware. Known for providing high-quality tableware, including bone china, Nikko is well known in the hotel and restaurant industry.

In April 2021, Nikko launched the project "NIKKO Circular Lab" to promote the circular economy of the ceramics business and the media "table source" to support the sustainability of restaurants, together with the sustainability promotion organization of the restaurant industry. , Also joined the Japan Sustainable Restaurant Association.

Why did the company start working on sustainability and the circular economy at this time? This time, we interviewed Mr. Naoki Mitani, Managing Director of the company, about the background and efforts.

Developed "Fine Bone China" which is said to be the whitest in the world

Nikko is a long-established company with a history of more than 100 years, which was founded in 1908 in Kanazawa, Ishikawa Prefecture. Originally, it started with the company name of Japan Hard Pottery Co., Ltd., which makes hard pottery. The purpose of the establishment was to manufacture high-quality tableware in Japan and earn foreign currency. In 1978, we developed "Nikko Fine Bone China" with the content of bone ash increased to 50%. It has come to be said to be the whitest in the world. Since its founding, the business has diversified, and in addition to the Ceramics Division, the housing equipment business and the functional ceramic products business have become the pillars of the business.

"Nikko Fine Bone China" was born in 1978 (Source: Nikko Co., Ltd.)

The crisis in the pottery business is an opportunity to reconsider the significance of existence

Why did Nikko decide to pursue sustainability and make circular tableware at this time? The big reason for this was that the spread of the new coronavirus added to the crisis facing the ceramics industry.

"I think the pottery business is a declining industry," says Mitani. Not only the company but also the Japanese ceramics industry as a whole continues to be in a very difficult situation. According to the Ministry of Economy, Trade and Industry and the Japan Ceramics Federation, the annual production value of "daily ceramics" has decreased by about 70% from 78.1 billion yen in 2003 to 27.1 billion yen in 2018. The reasons for the slump are the increase in cheap imports and the long-term recession.

Nikko's ceramics business has continued to decline since the 1980s, as the market is moving, but the company, whose main customers are hotels and restaurants, was directly affected by the new coronavirus.

Mr. Naoki Mitani, Managing Director, Nikko Ceramics Co., Ltd.

The "era in which the more you make, the more you sell" has already ended, but Corona has made the crisis even more apparent, forcing a structural shift in the business itself.

At this important turning point, Mr. Mitani came to reconsider the significance of the company's survival.

“As I was thinking about how to rebuild the ceramics business, I rushed into the Korona-ka and felt the need to seriously tackle sustainability, so I started to move forward company-wide,” says Mitani.

"Why do we make sense to carry out this business? What is the reason for the company to exist? What is a company that may exist? What does it mean to be good?" I realized again that I needed to increase the number of fans rather than the customers. In doing so, I realized that increasing the number of fans and working on sustainability are the same thing. "

Even if a crisis like Corona comes, restaurants with regular fans are strong. Even if they can't come directly to the store, they support the store's management in many ways. The same applies to the relationship between Nikko and its customers, restaurants and hotels.

Beyond the relationship between a supplier who pays tableware and a customer, in order for chefs at hotels and restaurants to support their company and become fans, it is necessary to have thoughts and visions that create empathy. That is the sustainability of food and the global environment surrounding food, which is a common issue for those involved in the same "food".

In the first place, Nikko has stated in its management philosophy that "the environment is also our customer," and has been seriously tackling environmental problems even before Corona. In that sense, it is natural for the company to put sustainability and the circular economy at the core of the ceramics business, and as a result, the business transition and internal penetration were able to proceed more smoothly than expected.

"Make, use, throw away" The actual situation of the linear type ceramics industry

According to Mr. Mitani, the reality is that even in the pottery industry, the current situation is a linear system of "make, use, and throw away." However, looking around the world, the depletion of high-quality soil and stones, which are the raw materials for ceramics, has become apparent, and it is said that there are some areas in Japan where the raw materials are on the verge of depletion.

Even in areas where there is still a small amount of raw material left, further mining will be difficult if buildings are built on the land. Pottery makers are everywhere searching around the world for quality raw materials, which is why prices are skyrocketing. Of course, the company, which features pure white ceramics, must also face this challenge.

In addition, there are many issues from the environmental point of view on the side of using tableware. Especially for commercial use, tableware tends to be used as a consumable item. Mr. Mitani's recognition is as follows. "In the market, there is widespread recognition that plates can be broken quickly, so cheap ones made overseas may be acceptable. However, on the other hand, the resource depletion of raw materials is progressing. is needed"

"NIKKO Circular Lab" which is the key to the transition to the circular model

"NIKKO Circular Lab" is a newly launched cross-organizational project with the aim of shifting the ceramics business to a more circular model, with the strength of the company's products that are highly durable and hard to break.

The theme of the lab is "Designing a circular future 100 years from now". Its mission is to create a business for the next 100 years of Nikko, a 100-year-old company. The lab is working on various projects throughout the product life cycle to realize the production of circulating ceramics in line with the principles of the circular economy. It is also interesting that the technical issues for them are also disclosed. Here, we will introduce some projects in the order of product life cycle.

Details of NIKKO Circular Lab Initiatives (Source: Nikko Ceramics, Inc.)

Circular design: Design to be used for a long time in advance

When trying to extend the life of a product, the first thing that comes to mind is the improvement in durability. At the design stage, the approach is taken from both the method of utilizing the durability that the company was originally proud of as its strength and the timeless design.

From the viewpoint of durability The pattern of the plate drawn with gold or platinum is easy to peel off. The wear speed cannot keep up with the company's high durability, and even the long-awaited durable products havetened to be discarded just by peeling off the pattern. Therefore, we have developed a decoration method "GP guard" that is 400 times more resistant to wear and 5 times more durable to dishwashers than conventional products.

Design perspective Tableware that colors food. It is not uncommon to buy a new one depending on the season and fashion. As a result, it leads to the disposal of products that can still be used. Therefore, the company set out to develop a "product that can be used for a lifetime" that is not obsolete in color and shape. It is a product that symbolizes Nikko, which can be used forever because it is simple. The series name is "Remastered". The series is carefully selected from tens of thousands of past designs and is scheduled to be released in mid-May. With a "timeless design", we pursue not only functional durability but also emotional durability.

The "design" stage is especially important in the transition to recycling products. The company attaches great importance to this stage, which influences the subsequent process, and has begun circular design efforts from various perspectives, such as recycling raw materials after firing and researching and developing alternative resources, in addition to durability and design. There is.

Raw material procurement: Cadmium-free pigment development

Cadmium and selenium are usually used when decorating in red or orange. It is indispensable for producing highly saturated colors, but it is a raw material that must be handled with care for safe handling. Of course, these do not leak out of the product and users can use it safely, but from the viewpoint of safety and security, the company has started to develop "cadmium-free" pigments that do not use cadmium. The focus was on the traditional technique "Kakiemon no Aka" that has continued since the early Edo period. It is currently under development for commercial production.

Use (Dish as a Service): Subscription for plate only

Maximizing the value of goods is an important foundation for the transition to a sound-cycle business. One of the concrete methods is the service conversion of products and the cyclical subscription as its business model. At the lab, we have started trial operation of a circulation-type subscription service specializing in plates (partition plates) at restaurants in Kanazawa City, Ishikawa Prefecture.

The target of this service is Nikko's fine bone china plates. The company will continue to charge customers for the ownership of the product. By having Nikko own the property, extending the life of the plate is an incentive for the company. The collected plates will be maintained, recolored, and remade to extend their life.

Until now, the durability of tableware, which is Nikko's strength, has led to the dilemma that new plates cannot be sold until they break. The Dish as a Service model is an excellent business model that solves this dilemma and leverages Nikko's strengths while achieving both customer value and environmental value.

So why is it only for plates? Mr. Mitani explains the reason as follows. “The restaurant I did test marketing used a wide variety of dishes of the same size. When I saw this, I had the impression that it was a bit lacking in unity. When you show me, there were a lot of plates piled up there. Of course, it costs money to replace all this amount with a unified plate. Therefore, we offer a subscription service that can reduce the initial cost. It was introduced on a trial basis and adopted by the store. "

"In addition, like this shop, there are many cases where we are particular about the main dish, but when it comes to the plate, it seems that we often do not pay attention to it. However, customers actually get it. It is the plate that is brought close to the mouth. I think that sticking to the plate will increase the satisfaction of the customers in the store, so I thought that we could contribute to that as well. It was unintended. However, as a result, the chef's feelings became even higher, which led to the purchase of the main plate. "

For restaurants, you can use high-quality plates while keeping the initial cost down, and you will be able to spend more on the main plate. If high-quality plates can be prepared for both the tray and the main plate, it may lead to an improvement in customer satisfaction and, in turn, an increase in sales. It is this subscription service that has the potential to bring not only environmental value but also economic cost reduction and sales improvement to the store.

Use: Regeneration of tableware by recoloring

Recoloring that regenerates tableware by recoloring products that have peeling or rubbing of patterns or gold wires. Until now, the design has worn out before the end of the product's life, so it has been discarded even though it can still be used as a product. On the other hand, recoloring is an attempt to bring the deterioration speed of the product itself closer to the wear speed of the pattern.

Tableware regenerated by recoloring

Use: Reproduction of non-standard products

The company's products are widely regarded for their high quality. Naturally, we have a strict quality control system in order to deliver products to our customers with guaranteed quality. Therefore, products that do not meet the in-house standards will inevitably come out. This initiative aims to make effective use of resources by remaking and recycling them. According to Mr. Mitani, recycling to crush non-standard products requires energy, so remake is the first priority.

In addition, these efforts seem to have an unexpected spillover effect within the company. According to Mr. Mitani, as a result of a series of activities, resource utilization beyond the framework of the business division, such as an attempt to use the waste tile material produced by the bank tulle division (custom-made system bus business), which is another department, as a raw material for ceramics.・ It is said that an up-cycle movement is being born.

Transition to a circular economy throughout the product life cycle

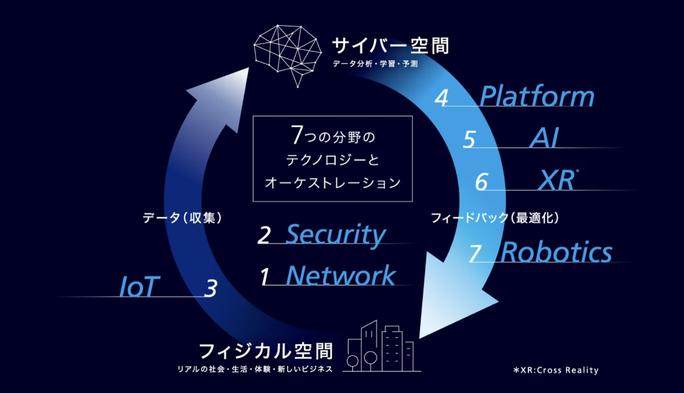

Overview of Nikko's Circular Economy (Courtesy of Nikko Co., Ltd.)

The figure above is an overall view showing the company's efforts toward the circular economy at the present time, which has been introduced so far. This figure is based on the idea of the Ellen MacArthur Foundation's butterfly diagram, which is a system diagram of the circular economy.

There are three main points in the company's diagram. The first is that it is envisioned to divide into "biological resources" that return to the soil in a short period of time and "depleting resources" that are difficult to return to the biosphere as they are, and to use them as separate cycles. The raw materials for tableware are soil and stone, and it is possible to build a circulation type model from both the biological cycle and the technical cycle. The second is that we are comprehensively working from the upstream stage to the downstream stage of the product. And third, smaller loops, such as repairs and refurbishments, are prioritized as having a lower environmental impact.

This overall view serves as a "face" that connects each activity (point). It also serves as a compass to know which means should be prioritized in the circular model.

"Table source" that supports the sustainability of restaurants

Nikko has not only promoted the making of circular tableware through the NIKKO Circular Lab, but also launched an owned media "table source" to support the sustainability of restaurants. The name "table source" expresses the desire to be the "source" of ideas that make the restaurant table more rich and sustainable, and bring smiles to the people around it. It is said that it is.

The media includes the latest news and columns on food sustainability, interviews with restaurants and companies working on sustainable manufacturing, and the NIKKO Circular Lab's efforts.

To become a sustainable company that will be needed for the next 100 years

We asked Mr. Mitani about future developments. "There are a lot of things I want to work on. For example, product development in collaboration with the member restaurants of the Japan Sustainable Restaurant Association (SRA), which we are a new member of. Together with people who can sympathize with our efforts. I am honored to be able to do this. "

The company's challenge has just begun. "I have the pride that I am making good things, so I want to keep products and companies in any form, and I have the feeling that I have to aim for that in order to run a business. , I would like to work on sustainability while interacting with the shop staff and increase the number of people who can become Nikko fans, "says Mitani.

In order for Nikko, which has been in business for over 100 years, to survive for the next 100 years, people who are engaged in food-related businesses from various standpoints, such as producers, restaurants, hotels, and suppliers, as well as the global environment surrounding food. At the same time, it is necessary to work on the sustainability of the entire industry. Joining SRA is a step towards that, and the real journey is about to begin.

Editor's Note

Until now, the sustainability issues surrounding tableware have not been widely recognized. It is expected that the problem will become more serious as the depletion of raw materials continues in Japan and overseas. Even in Japan, as the industry itself was sluggish, Mr. Mitani's "question", "If a company exists, what is it for?" Left an impression on me. I felt that this fundamental question led to business transformation on the axis of sustainability and circulation, not as a charitable business separate from business and main business. This is because the company is not aiming to circulate a part of the manufacturing process, but is approaching the entire business model and product life cycle that are the basis of the business. Although I couldn't introduce it this time, the company is already steadily advancing innovative circular economy initiatives other than those mentioned above. I would like to continue to pay attention to what kind of impact Nikko's transition to the circular economy will have.

[Reference site] Nikko Ceramics Co., Ltd. [Reference site] table source [Reference site] Japan Sustainable Restaurant Association

Tagged with: Sustainability, Asia, Social Good, Hotel, Reuse, Upcycle, Japan, Manufacturer, Social Good, Restaurant, Circular Design, Own Media, Circular Economy, Restaurant, Japan Sustainable Restaurant Association, Tableware, Ishikawa Prefecture, NIKKO, Nikko Co., Ltd., Nikko, Western Tableware, Tableware Maker, Circular Economy, NIKKO Circular Lab, Bone China, Sustainability Transformation, table source, Table Source

![lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool] lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/28016.jpeg)

![lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/30293.jpeg)

Kitchen Equipment Every Restaurant Needs

The IKEA wood box was a great help in preparing breakfast! There are too many other uses ~

lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products

Just put it on the cafe feeling at once!Enriched Cafe Item in Nitori (January 24, 2022) --Excite News